Interface Test Adapters - ITAs

An Interface Test Adapter (ITA) is used to connect the specified Unit Under Test (UUT) to the Intermittent Fault Detection & Isolation System (IFDIS).

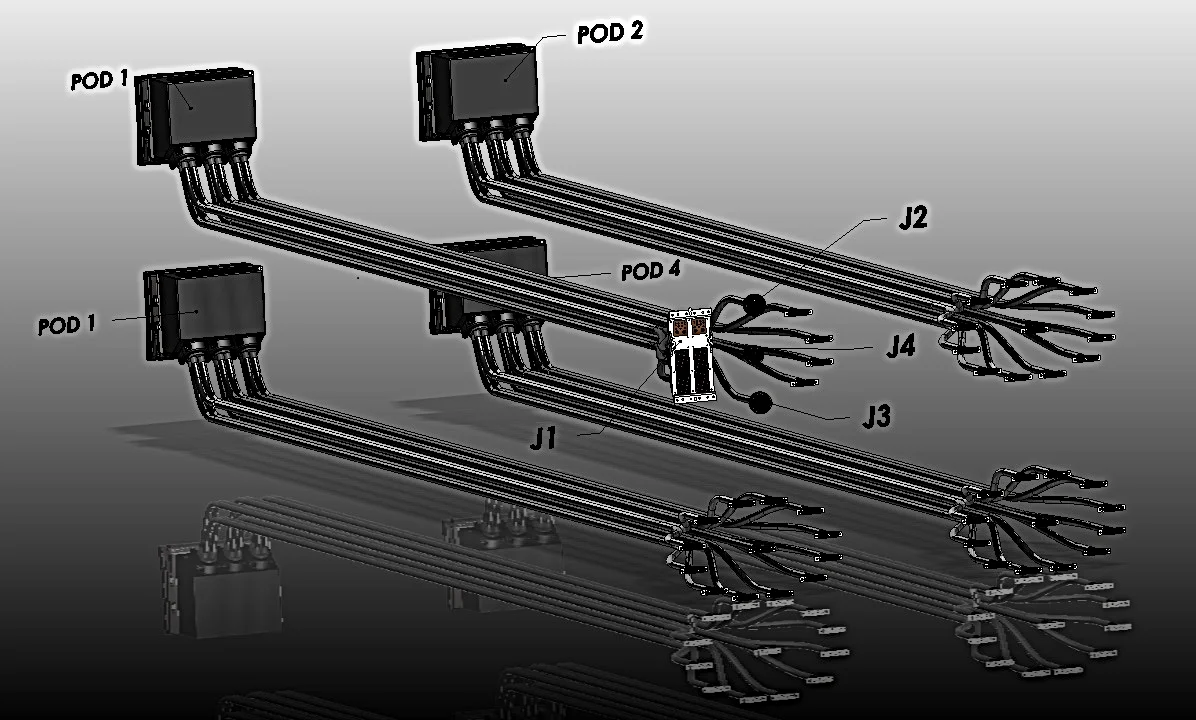

Figure 1: LRU Populated with ITA Cards

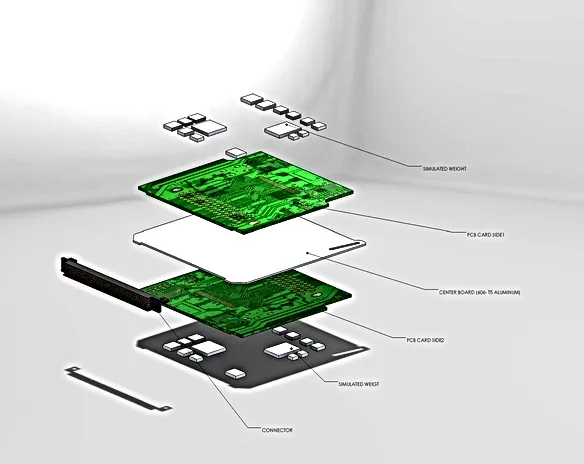

Figure 2: MD11 Flight Control Computer ITA

Figure 3: ITA Card Exploded View

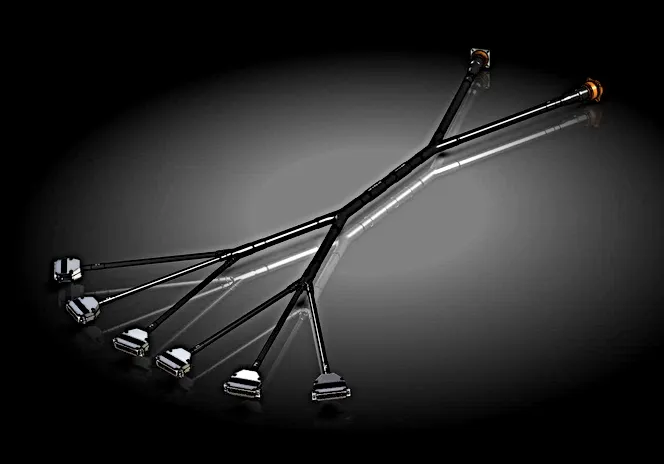

Figure 4: VIFD Interface Adapter Cable

Each ITA simulates the form and fit of all UTT connections (Cards, Front Connectors & Rear Connectors) both internally and externally

The component parts of a Line Replaceable Unit (LRU) ITA are as follows: Virginia Panel Connector(s), 24 gage wire in cables of 100 wire each (as many as required to make all connections), circular front facing connectors, rear facing connector(s), replicas of each circuit card installed in the LRU to interface with the LRU Backplane and a Fixture used to mount the UUT within the environmental chamber.

The cost of an ITA is a function of it’s complexity, including Cards required to be installed in place of the active CCAs, assembly time, quality verification of individual parts and the completed assembly, and testing (static & dynamic).